Production and printing of label products

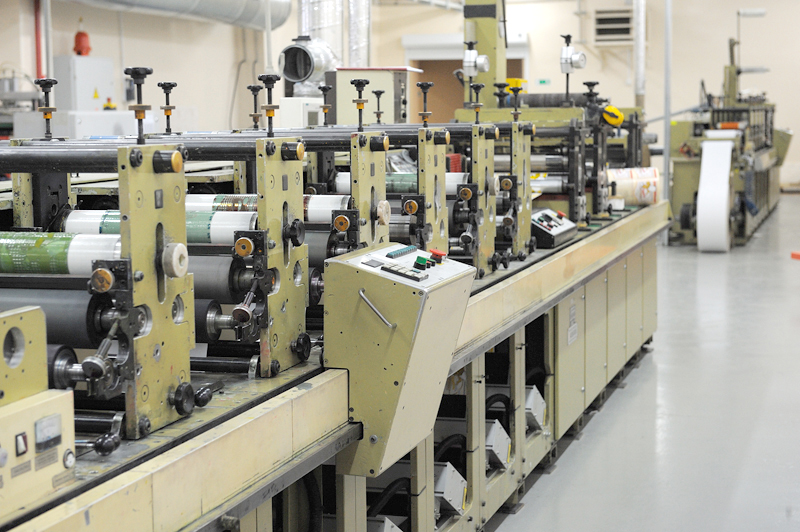

In 2012, the company “NTS” organized the production of self-adhesive labels of various shapes and sizes, using flexographic printing.

Flexography is a direct high rotary form of printing in which fast drying liquid ink (UV-rejection and alcohol)is applied to various surfaces by means of flexible rubber (or other elastomeric) printing plates, that are mounted on form-cylinders with different circumference, which allows you to choose any size of the finished product.

This type of printing is very widely spread in the label and packaging products market, since none of the other known types of printing allows to print so quickly and efficiently on different roll materials: film, paper, self-adhesive paper, metallized film and paper, fluorescent self-adhesive paper and so on.

Advantages of flexographic printing:

- Highquality of printing

No blur or pale colors, you get products with a bright clear picture with an ideal color rendition – exactly the same as in your layout design. Every detail, even the smallest, is perfectly printed. - Safety

During the application of images on paper packaging, as well as during the use of the package, no harmful substances are released. Such packaging is completely safe for the environment, and for our health. - Reasonable price

The low cost value of the stamps (flexoforms) enables significant reduction in costs for the production process. - Efficiency

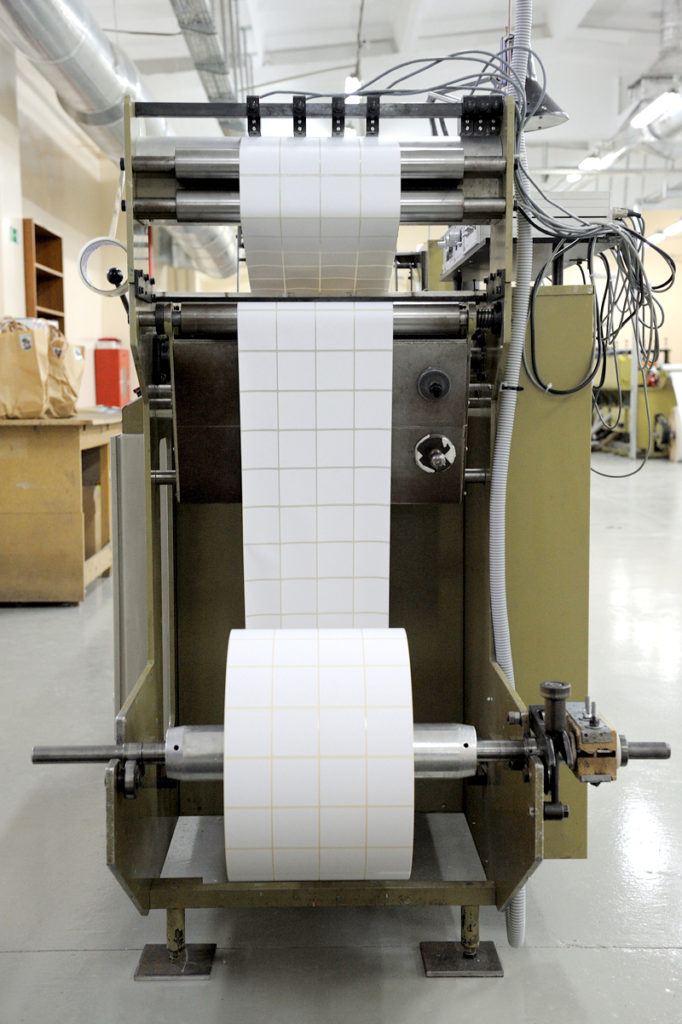

Allowing us to use materials for printing in rolls, which is more convenient and more profitable than sheet label analogues, itinvolves high-quality printing on the whole area at high speed (up to 600 m/min).