Республика Беларусь

г. Гомель, ул. Хуторянского, 35А

Диспетчер

+375232 23-10-10

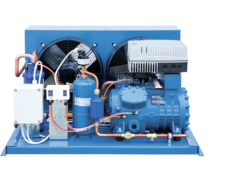

Фреон. Комплектующие для

холодильного оборудования

+375 232 22-33-74

+37544 517-17-18

Салук Дмитрий Александрович

e-mail: dmitriy_saluk@ntsretail.by

Расходные материалы и

электротехническая техника

+37544 550-59-05

+375 232 22-33-74

Мелешко Тимофей Валерьевич

e-mail: 8044550-59-05@mail.ru

Торговое холодильное оборудование

+375 232 24-62-33

+37529 384-04-30

Широков Александр Сергеевич

e-mail: shyrokov_nts@mail.ru

Вентиляционные системы

+375 232 22-32-09

+37544 536-36-96

Жедик Сергей Николаевич

e-mail: ntsvent@mail.ru

Испытательная лаборатория

Начальник лаборатории

+375 232 22-45-45

Инженер лаборатории

+37529 232-97-92 (МТС)

+37544 593-45-33 (Velcom)

Факс +37232 23-12-13

г. Речица, ул. Луночарского, 97А

Диспетчер

+375 2340 3-26-99

+375 2340 6-59-79

г. Мозырь, ул. Пушкина, 27

Диспетчер

+375 236 20-10-52

+375 236 25-62-45

Licenses and certificates

The service department ofthe NTS ALC consists of well-qualified mechanical and electrical engineers, who have great experience and high professionalism.Service teams are equipped with professional tools and all necessary expendables.In the company’s storehouse, there are all necessary spare parts, which can replaceout of order ones. Having our own cars and trucks park, we ensure the mobility of work.

All the equipment, installation work and commissioning are certified.

For trouble-free operation of commercial refrigeration equipment, it is recommended to carry out maintenance work at least once a month and every half-year –permanent repair.Particular attention should be paid to the mandatory grounding of refrigeration units and starters. Groundingshould be checked periodically.

For trouble-free operation of commercial refrigeration equipment, it is recommended to carry out maintenance work at least once a month and every half-year –permanent repair.Particular attention should be paid to the mandatory grounding of refrigeration units and starters. Groundingshould be checked periodically.

Maintenance service:

- checkingof completeness and technical condition of the product.

- checking of the reliability of fixation and the absence of mechanical damage to the protective grounding (neutral grounding)

- inspection of electrical equipment, automation devices and tightening of electrocontact connections

- checkingof the position of the adjusting screw of the circuit-breaker (carried out visually),

- checking of the lightning (triple switch on and off the toggle switch “light”)

- checkingof the operation of the evaporator defrosting system and the condensate current (by pressing the thermoregulatory button all the way out)

- removal of dirt and dusting of refrigerating machine’s condenser

- checking of the refrigeration system tightness (in the places of welded and detachable joints)

- Checking of the temperature condition and its adjustment (measuring the temperature in the center of the cooled volume

Permanent repair includes:

- carrying out the work stipulated in maintenance

- checking of magnetic starter and contact joints

- cleaning the condenser of the cooling unit from pollution

- checking the resistance between the clamp “ground” and the metal parts of the cabinet, which can be energized as a result of insulation failure;

- depending on results of defecation: replacement or repair of dehumidifier and automation devices

Service maintenance of ventilation equipment and air conditioning systems ensures their correct operation for a long time.Moreover, timely maintenance of ventilation equipment, maintenance and repair of ventilation and heating equipment, air conditioners arenecessary for maintaining the health of people who use these systems.

Types of maintenance of air conditioners:

- One-time maintenance of air conditioners. In this case, the air conditioners are serviced once, at the customer’s request.A service engineer arrives and performs the service once.

- Quarterly maintenance of air conditioners and ventilation with a contract. The service is carried out once a quarter. A maintenance contract is concluded and maintenance of air conditioners is performed every three months. This is well suited for large companies in Minsk, where ventilation and air-conditioning are located, especially for server rooms. In this variant, maintenance and repair of air conditioners is carried out in Minsk and throughout the Republic of Belarus.

- Annual maintenance, similar to the quarterly maintenance of air conditioners, is conducted four times a year or more often, depending on the сustomer’s specifications and equipment serviced.

Scheduled maintenance.

This type of maintenance (MNTC)provides a set of work to clean the external and internal elements of the system, replace the filters and check the ventilation equipment for malfunctions in its operation.It is recommended to carry out this MNTC at least twice a year, but it is possible to do it more often (depending on the mode of use).

Unscheduled maintenance.

In case of equipment breakdown or an emergency, the Customer must issue an application for the servicevisit. Scheduled arrival of specialists at the object for the repair of ventilation systems is carried out within 2-3 working days.

Unscheduled maintenance – emergency.

The conditions for performing emergency maintenance are the same as in the previous paragraph; the difference is that the work is carried out within 24 hours.

We offer the conclusion of contracts with customers and third-party organizations for long-term maintenance of equipment.The specialists of our service center are engaged in servicing both the territory of Gomel and the Gomel region.Our company is trusted by such giants as: